|

|

|

|

#1 |

|

Humidor Builder

|

I have recently acquired a client that wants a humidor with rather different dimensions than what I usually build.....

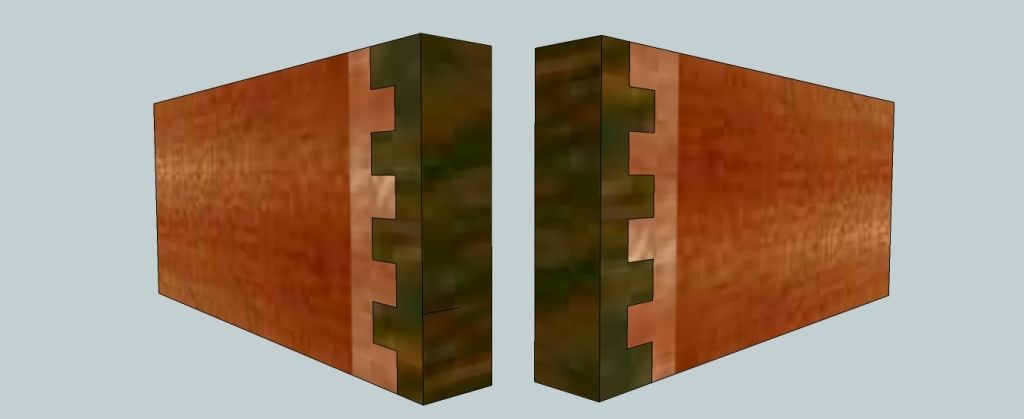

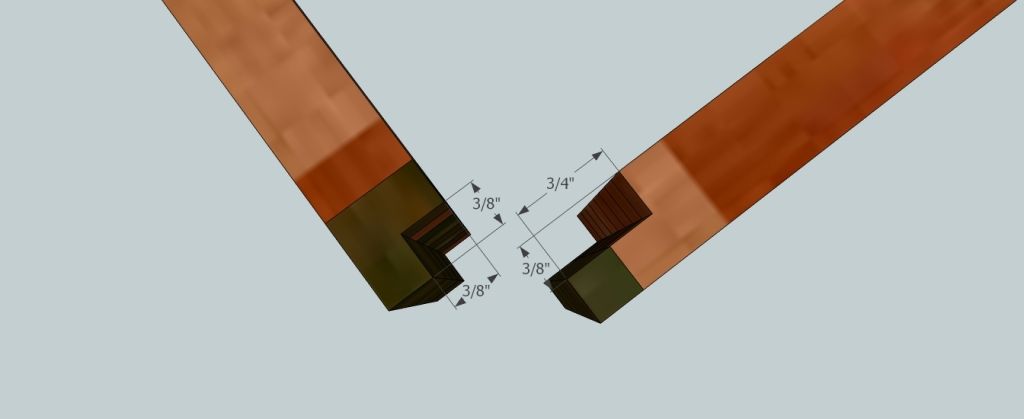

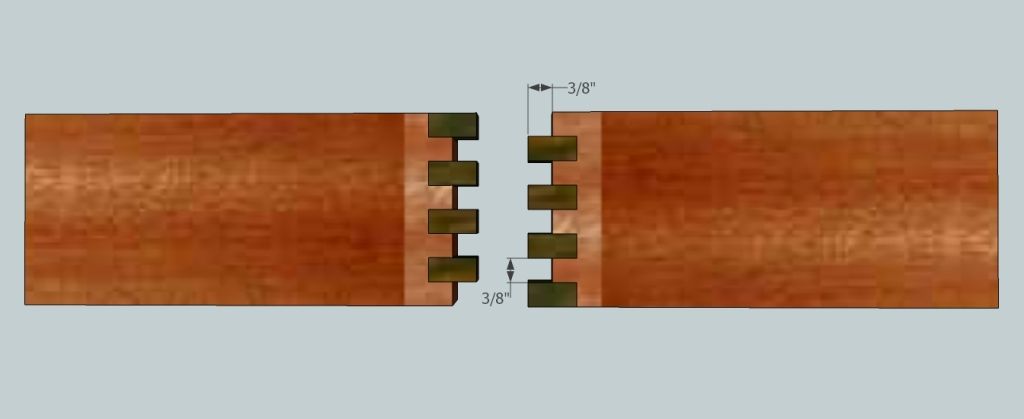

I love projects like this that force me to "think inside the box"..... Man, I'm glad I never listened to those folks that told me to always think outside of the box.... At any rate.... here's what my client wanted...... A cigar humidor that is tall and opens on the front like a refrigerator..... with a stack of trays within that pull out to select his favorite stogie....... 12.5" x 12.5" x 24" tall.... Constructed from Wenge & Sapele..... Well, my life partner, Terri.... loves to get involved and provide me with abstract ideas that she sees anywhere she sees them.... you'll know what I mean in a few short sentences.... To start things off..... I built this display case with roughly the same dimensions.... probably a little shorter than the 24..... but, generally the same.... Well, she didn't like it.... said it was too plain.  The new project will be all wood, no glass..... My gal said she wants it to emulate a building..... if we're going tall.... she tried very hard to describe what it was that she wanted me to do.... and I, of course, was hearing something completely different... (don't ask).... Until she found some pictures of what she was trying to say..... So, here's the first challenge that was thrown at me..... "I want the corners to look like what they did to these buildings".....   Now.... me, really not thinking before I speak.... which I often do.... nodded my head and said... "no problem, baby".... So.... that sent me thinking..... How am I going to pull this off.... Sheesh..... looks simple enough.... Ever hear of rubik's cube.... well, anyways.... Here's what I've figured out.... Using a box joint with a 3/8" box joint/dado blade.... I first have to "box joint" in 3/4" width Wenge ends to the sapele.... (Note) Pictures are not to scale, nor a rendering of the project.... but a tool I used to figure out the cuts....

__________________

This correspondence has killed no trees, however, several electrons have been disturbed!

|

|

|

|

|

|

#2 |

|

Humidor Builder

|

Then.... the front & back panels (the one on the right in the photo)..... need to have a rabbet cut.... as well as the side panels.... also shown....

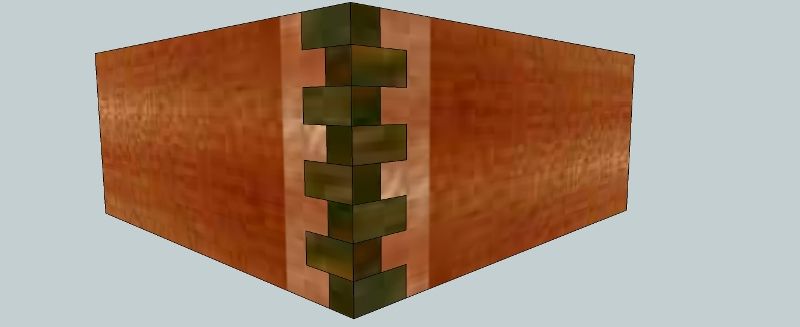

Then.... back to the box joint jig.... and cut these...  And.... with any luck.... I'll be able to get four corners to look like this all the way up....  Here's a pic of my materials..... Wish me luck and we'll see what the little lady has in mind..... At this point... I have no clue.... but, we're off & running..... I plan on blogging this if there is interest....

__________________

This correspondence has killed no trees, however, several electrons have been disturbed!

|

|

|

|

|

|

#3 |

|

Møøse bites can be nasty

|

That is going to be beautiful.

__________________

My neighbor came by my house this morning at 2AM, pounding on the door. Good thing I was still up playing the drums.

|

|

|

|

|

|

#4 |

|

Feeling at Home

|

Needless to say, I hired the right man [and lady!!] for the job. I will be following my tower of bliss consistently. Thanks for the pics Ed, I'm beyond excited at this magnificent creation we've embarked upon.

|

|

|

|

|

|

#5 |

|

Shipmate!

|

That is so Rad, you are the most awesome with humidor ideas.

|

|

|

|

|

|

#7 |

|

Humidor Builder

|

Off to a slow start... have about 5 humi's on the bench right now that I need to get cleared off... just staring at the Sapele & Wenge laying on the sawhorses..... I think I finalized my "attack" on the panels..... disregard the lid... that piece is just there to put a cover on the picture.... plus, I'm going to put a base molding on it...

__________________

This correspondence has killed no trees, however, several electrons have been disturbed!

|

|

|

|

|

|

#10 |

|

Humidor Builder

|

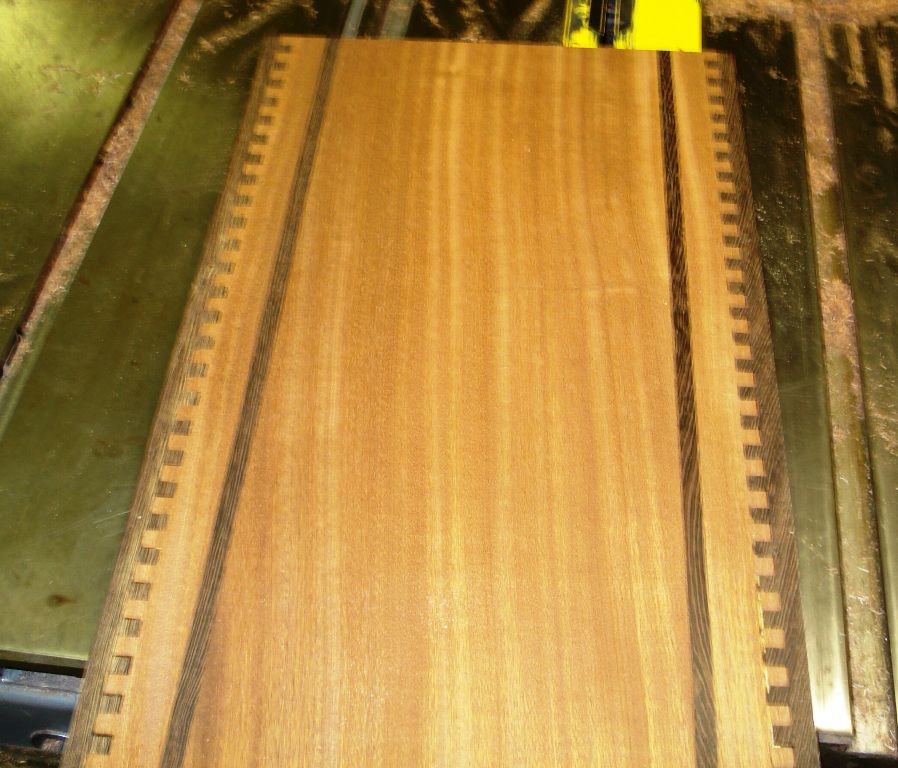

I got the easy part done today.... measured and milled all the pieces together to build the panels...

Next step - not so easy.... but, hopefully... it'll go well... Here's how the panels look so far... Gorgeous combination, in my opinion.....

__________________

This correspondence has killed no trees, however, several electrons have been disturbed!

|

|

|

|

|

|

#11 |

|

Feeling at Home

|

My arousal level is high, might I add. I keep pressing refresh hoping it acts as a time machine and transports me into the future :-D

|

|

|

|

|

|

#12 |

|

Il megglior fabbro

|

Looks great. Don't think it'll hold humidity too well in its present configuration however.

__________________

Ninety percent of everything is crap - Theodore Sturgeon. |

|

|

|

|

|

#13 |

|

Never Satisfied

|

This is going to turn out great. Can't wait to watch the steps of it being built.

__________________

Why would I? More like why wouldn't I... Hahaha |

|

|

|

|

|

#14 |

|

Humidor Builder

|

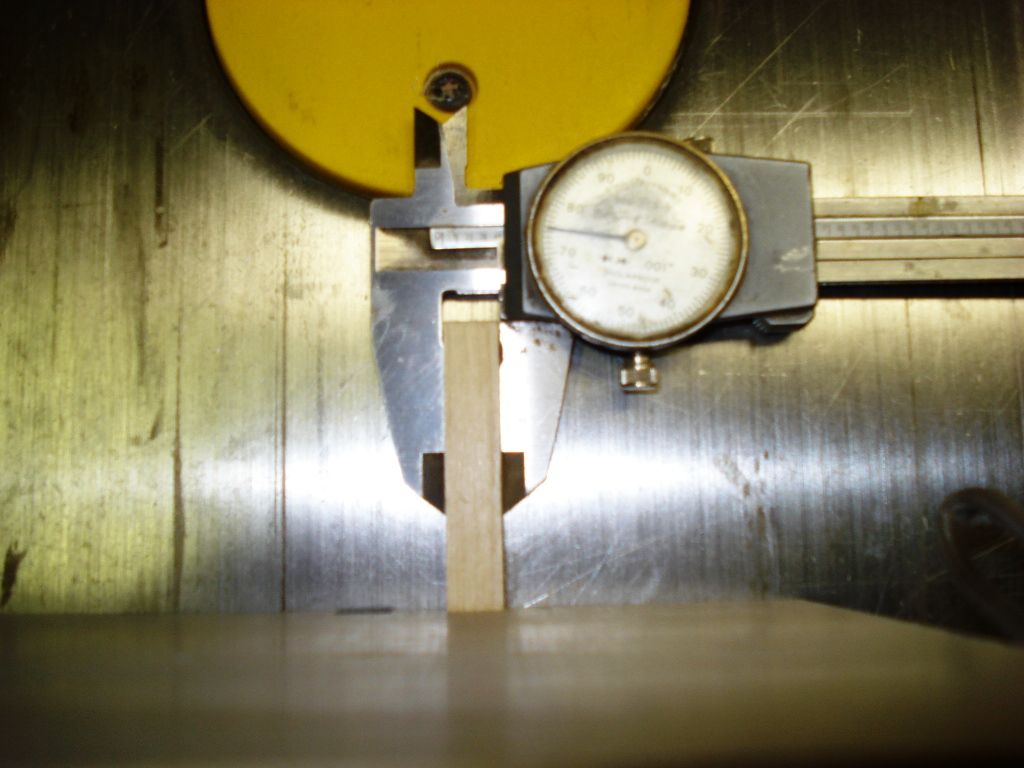

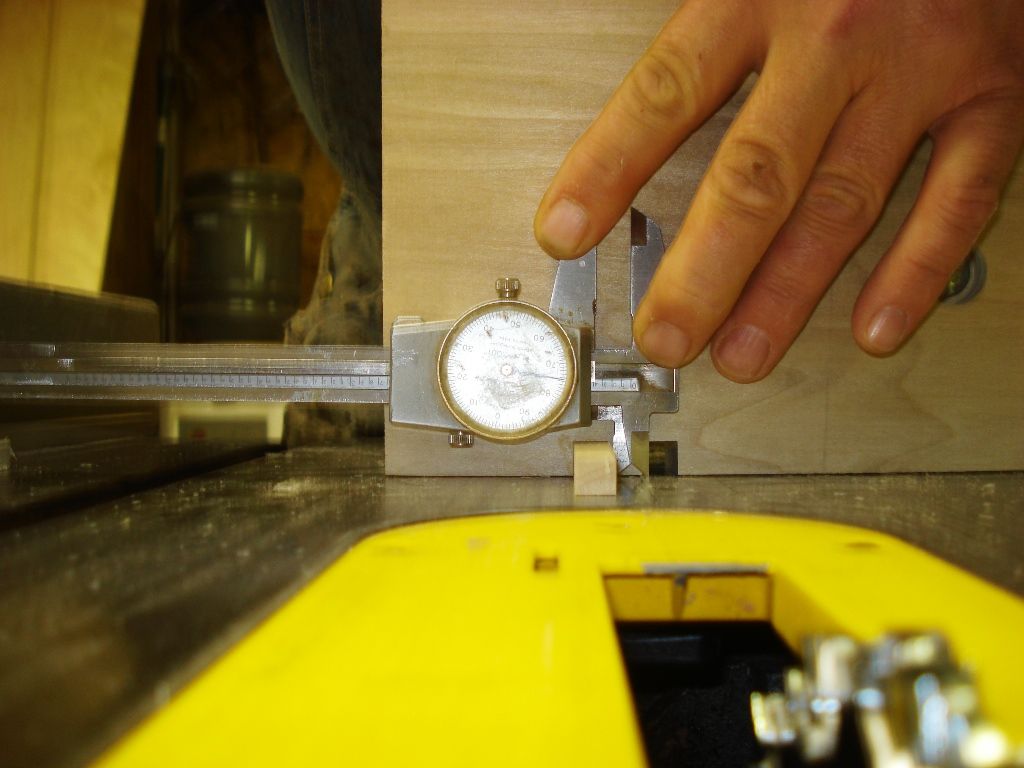

This step involved building a box joint jig first... I have a commercial jig, but... it didn't seem to have enough "heft" for what I needed today... so, I butchered up a piece of popler to make me a jig....

In setting up the jig... it is critical to make sure that the key, the space between the key and the blad and the blade all are equal.... otherwise, you'll run in to problems... so, great care must be taken to ensure that they are.... test cut and adjust, test cut and adjust was the order of business for the first 20 minutes or so..... Measured the key.... sitting pretty at .375  Measured the space between the key and the blade.... also, sitting pretty at .375  Finally, measured the space cut by the blade.... and, yep.... it was .375  Time for some test cuts..... I have a couple of lengths of poplar that I used. I made a "key" spacer out of a piece of scrap poplar that is also, yep... .375. This is used to properly place the side piece as the box joints alternate..... so you need to account for this. I cut two pieces at a time. A front/back piece and a side piece....  Then you simply make your first cut.... and then move the work pieces over to fit snuggly on the key. And cut again, repeat until finished.

__________________

This correspondence has killed no trees, however, several electrons have been disturbed!

|

|

|

|

|

|

#15 |

|

Humidor Builder

|

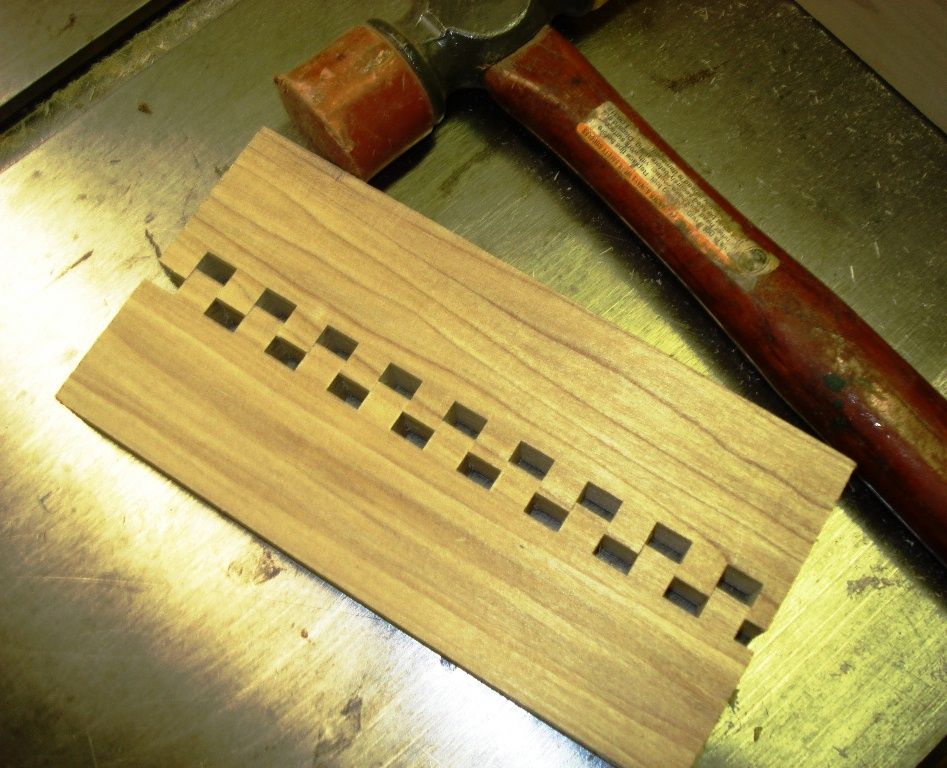

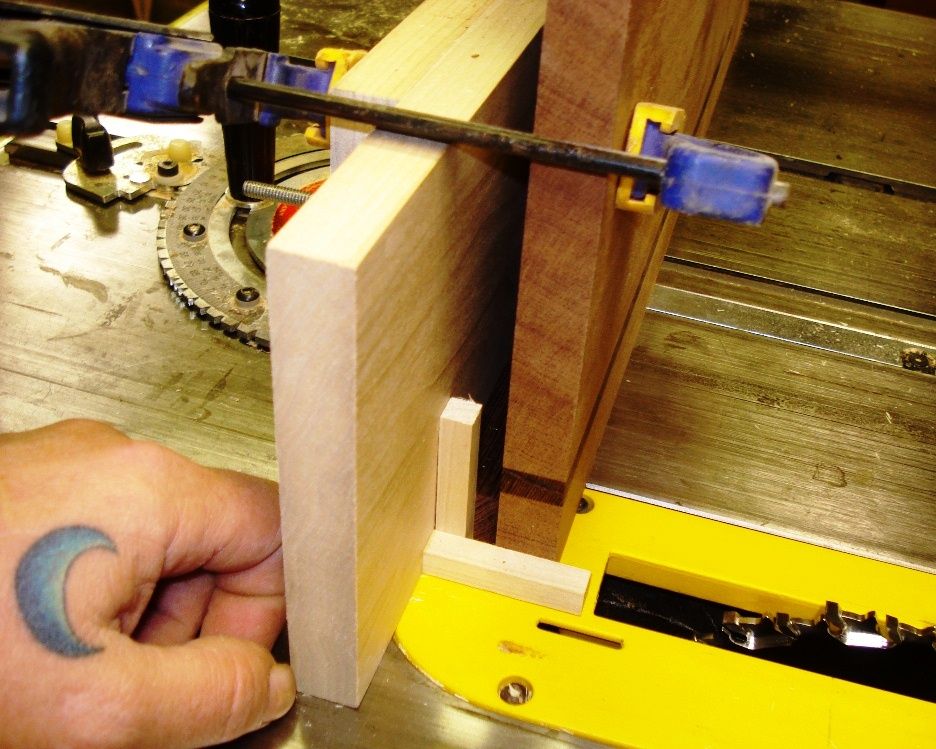

You should end up with something like this....

A few taps of the dead blow hammer..... you should get something like this....  Time for the real deal.... Since my panel is 11-1/4" and the piece of wenge that I'm joining to it is only 3/4", I needed to make sure the wenge was firmly in place behind the panel, and adjusted in there with the spacer block.  I used a couple of pieces of wood (not necessarily scrap) that was planed earlier to the same thickness as the wenge & sapele panel as both a spacer and a hold down for the 3/4" piece of wenge behind the sapele....  All systems go!

__________________

This correspondence has killed no trees, however, several electrons have been disturbed!

|

|

|

|

|

|

#16 |

|

Humidor Builder

|

A few tedious minutes later....

A few more tedious minutes later.... and this was the result I was looking for..... Phew! Four of these and I was ready to go home and watch some football....  It'll be a little while before I get on to the next step... I have a few other (day to day) things to get done.... as you can imagine, this requires all of my attention.... no multi-tasking allowed here... lol Thanks for following!

__________________

This correspondence has killed no trees, however, several electrons have been disturbed!

|

|

|

|

|

|

#17 |

|

Feeling at Home

|

Sweet mother of God. Flawless. I was on the edge of my seat like.. Rockets Engage, systrms check imminent.. Prepare for takeoff!

|

|

|

|

|

|

#19 |

|

Humidor Builder

|

This has been a real head scratcher... but, so far, it's going as planned....

The base & the lid will tie in nicely with the bands that I put in her..... Needs a lot of sanding...... and I'm still undecided on the base and the lid... but, I have ideas floating around...

__________________

This correspondence has killed no trees, however, several electrons have been disturbed!

|

|

|

|

|

|

#20 |

|

Guest

Posts: n/a

|

Looks Amazing...

Beautiful Joints... I love the wood grain patterns... |

|